Basisline Level 3

PCBs like in Level 2 - in addition with negative resist and galvanic plating through hole

additional in Level 3

raw material cut to size

(Ne-Cut)

CNC-drilling and

contour routing

(BUNGARD CCD/2)

brushcleaning

(RBM 300)

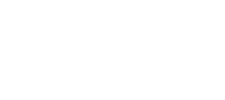

galvanic plating

through hole

(COMPACTA 30)

brushcleaning

(RBM 300)

lamination

of tenting resist

(RLM 419p)

vacuum exposure

(HELLAS LED)

spray developing

(SPLASH D)

spray etching

stripping of tenting resist

(SPLASH CENTER)

brushcleaning

(RBM 300)

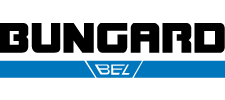

chemical tinning

(SPLASH CENTER)

lamination

of solder mask

(RLM 419p)

exposure of solder mask

(HELLAS LED)

spray developing

(SPLASH D)

curing of solder mask

(HELLAS LED or hot air oven)

CNC-V-cut or contour routing

(Bungard CCD/2)

System features:

- Fine-line technology in industrial quality with green solder mask and blue components printing!

- (To make components printing repeat the steps laminating, exposure and developing with blue tenting resist!)

- Modular upgradeable to multilayer, artwork production, waste water treatment or surface finishing set at any time!

- Track resolution: better 150µm!

- Film production with laser printer or bubble jet or local film supplier.

- Processing time: approx. 2 hours

- maximum throughput: 0,8m² / 8h

- maximum usable size: 210 x 300 mm

- 3 more machines than Level 2: Ne-Cut for board cutting, RBM 300 for cleaning and roughening and COMPACTA 30 for galvanic through hole plating (PTH)

Rilkestrasse 1

D-51570 Windeck

+49 2292 / 9 28 28 - 29

DE

DE  EN

EN  ES

ES  FR

FR