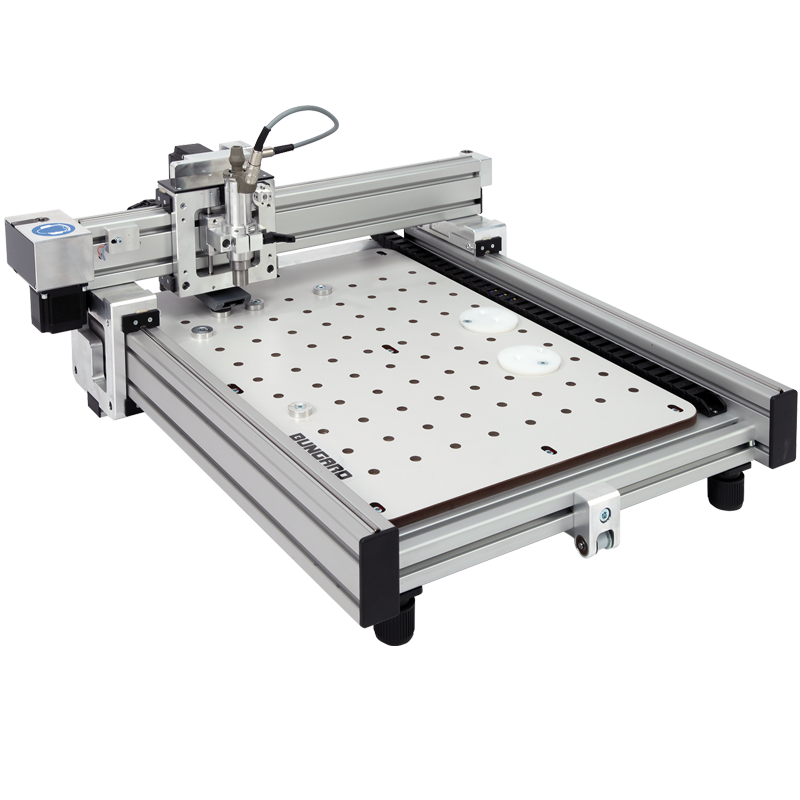

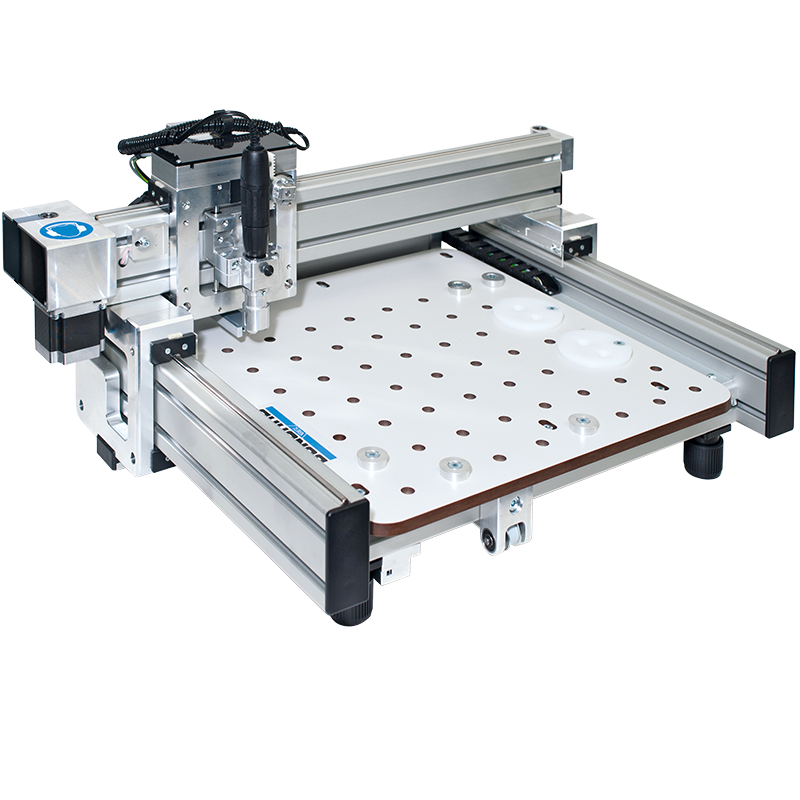

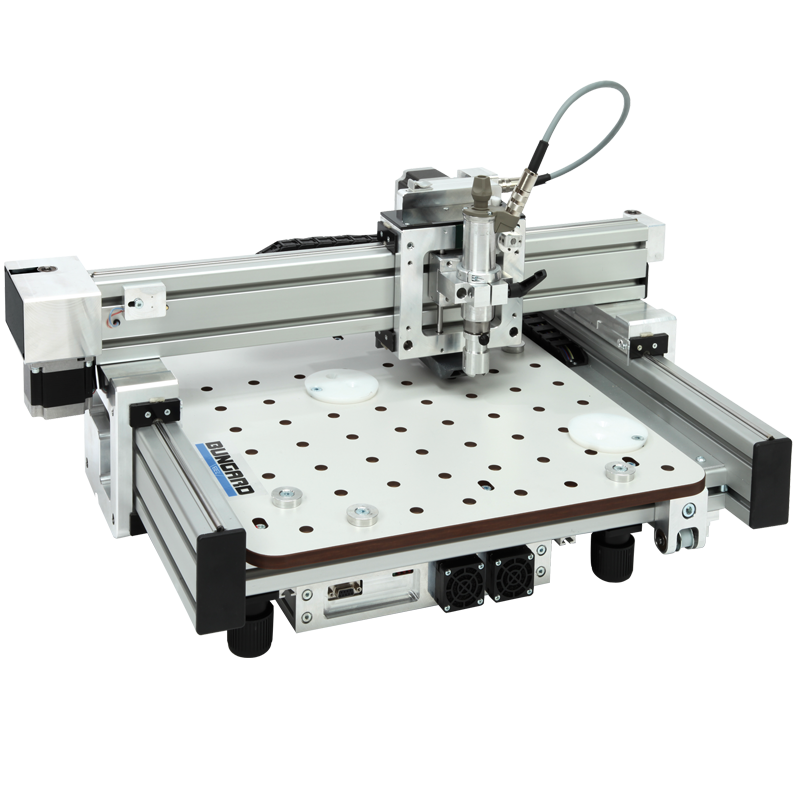

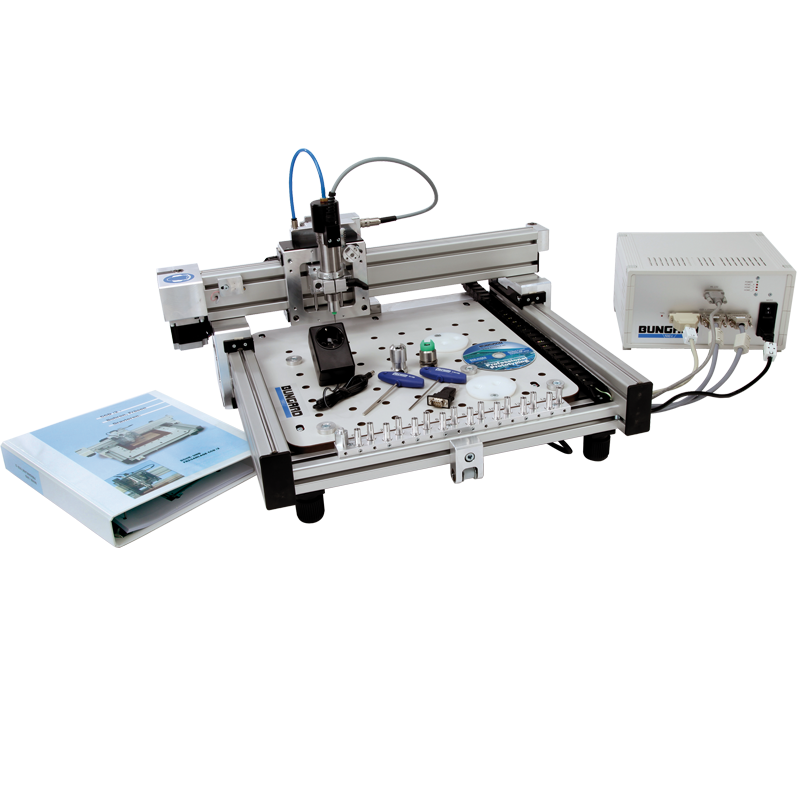

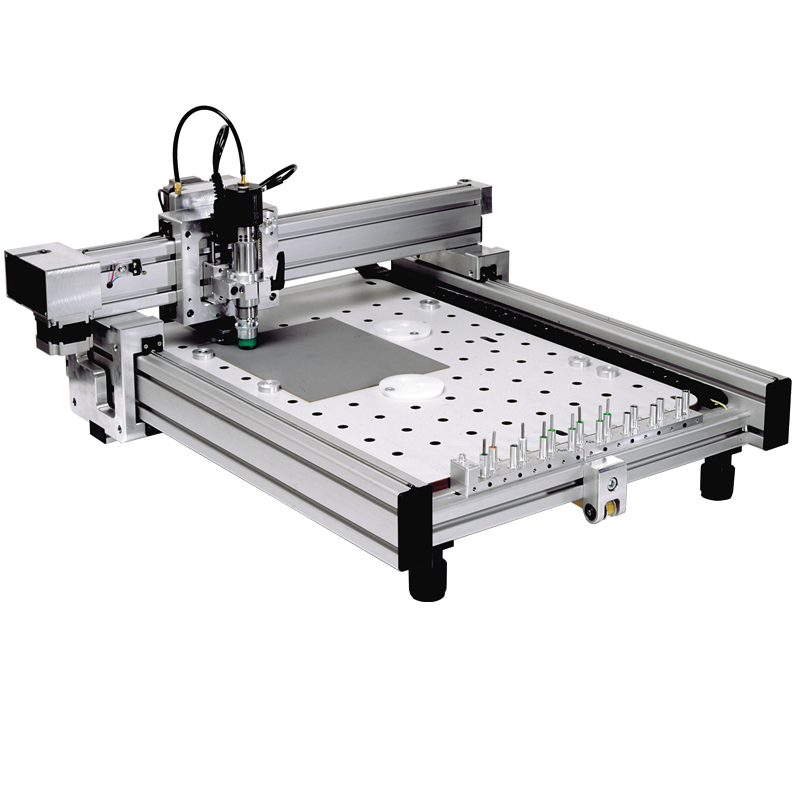

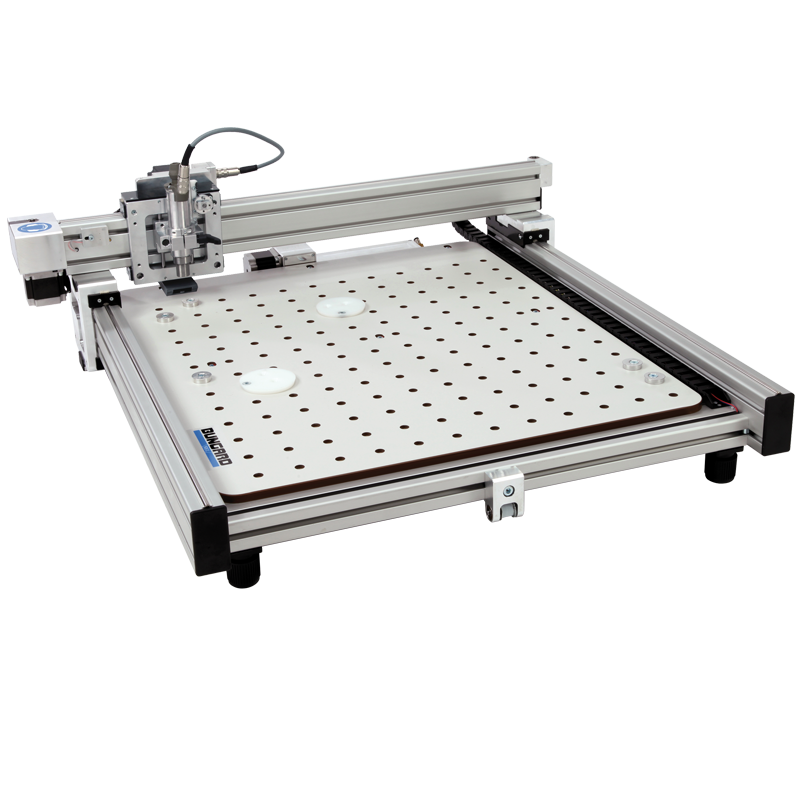

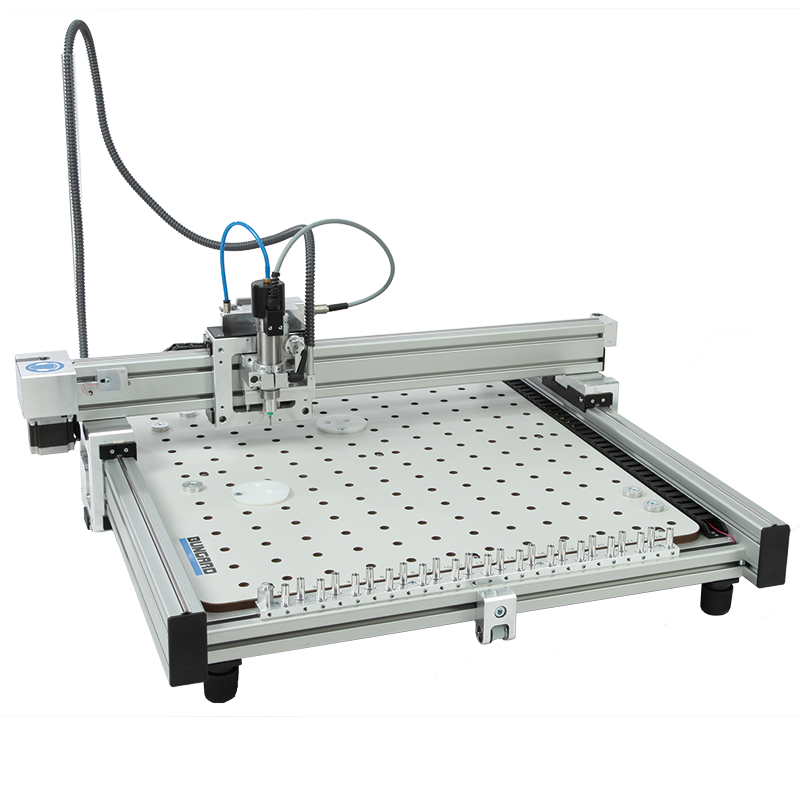

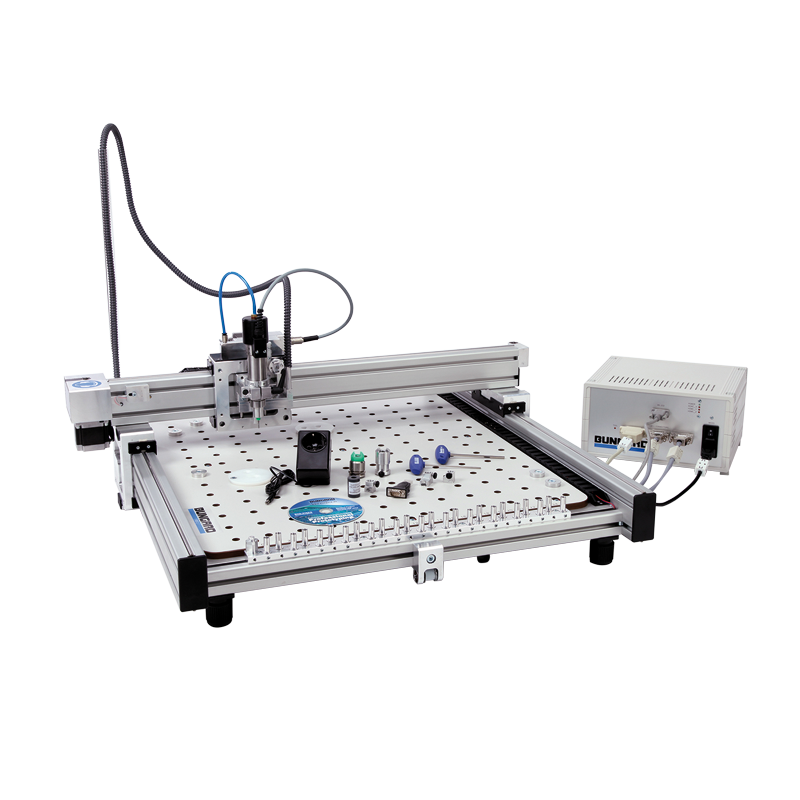

CNC machine

CCD/MTC

The Bungard CCD/MTC is a high quality computer controlled drilling and milling machine with semi-automatic tool change (MTC = manual tool change).

The CCD/MTC differs from the CCD/2 by a larger working area (325x495 mm in contrast to 270x325 mm) and by a separate controller.

Compared to the ATC models, the software interrupts the operation during the tool change and the new tool is changed manually (turning the knob changes by a quarter turn; motors remaine empowered and hold the position).

With the sturdy spindle and the good fixation of the tool in the chuck the Bungard CCD / MTC is perfectly fi tted for routing or engraving plastics, aluminium and other metals. 19 inch rack boards can also be processed.

Dimensions (LxWxH): 700 x 800 x 300 mm

Work area: 325 x 495 x 38 mm

Traveling speed: 1 - 9000 mm/min

Mech. resolution: step resolution: ⅛ mil (= 3.175µm)

EN

EN  DE

DE  ES

ES  FR

FR