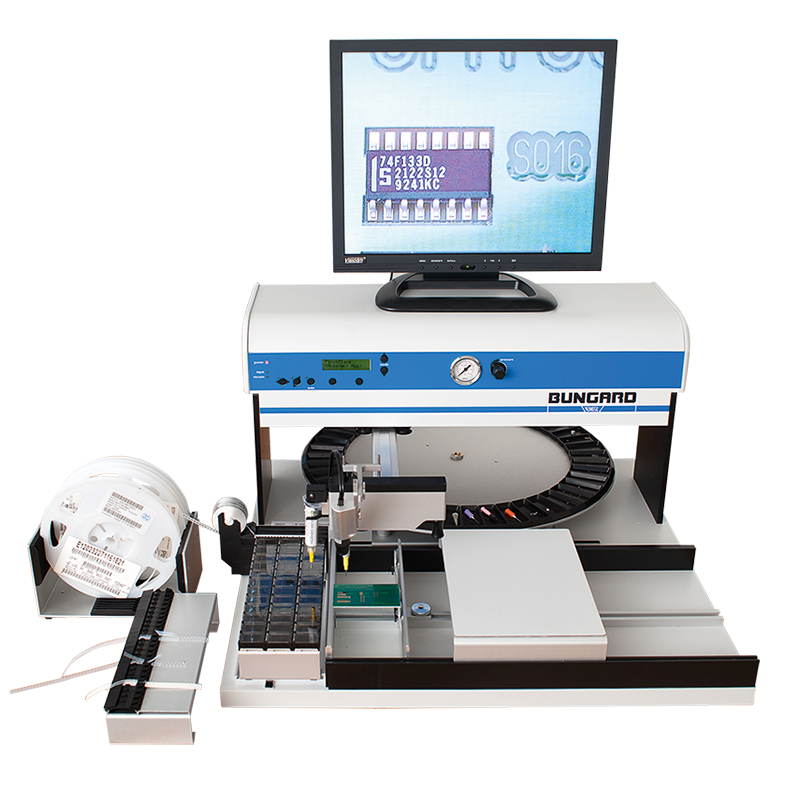

Pick&Place

SMT 3000

Manipulator for the production of prototypes and small series. The patent-registered Pick & Place head enables the comfortable handling of SMD-components. The modular-built system can be confi gurated for every use. It realizes the complete process - starting by dispensing of solder paste or glue up to assembling different components.

Assembling: 300-600 SMDs/hour

Dimensions (LxWxH): 600 x 600 x 345 mm

PCB thickness: 0,5 mm to ~ 4 mm

max. PCB size (LxB): 440 x 245 mm

DE

DE  EN

EN  ES

ES  FR

FR