Multilayer press

RMP

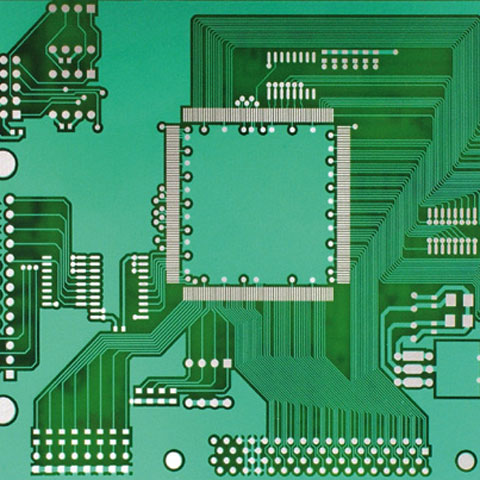

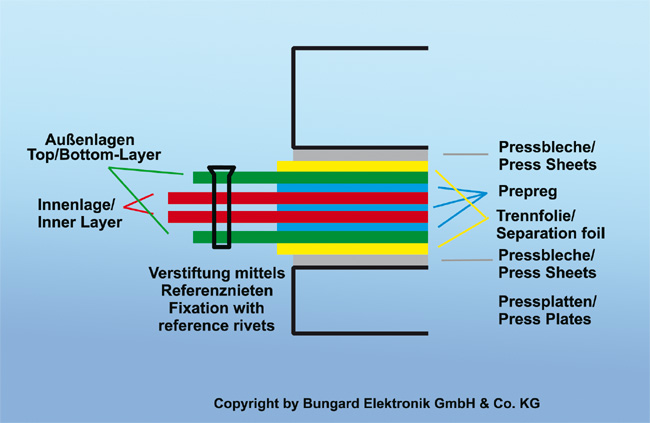

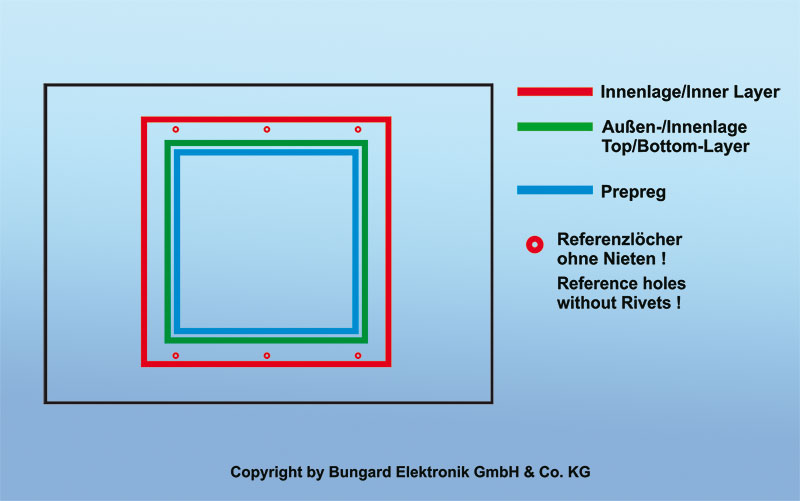

This high performance multilayer press was designed for PCB labs to enable quick prototyping of multilayer PCBs according to industry standards.

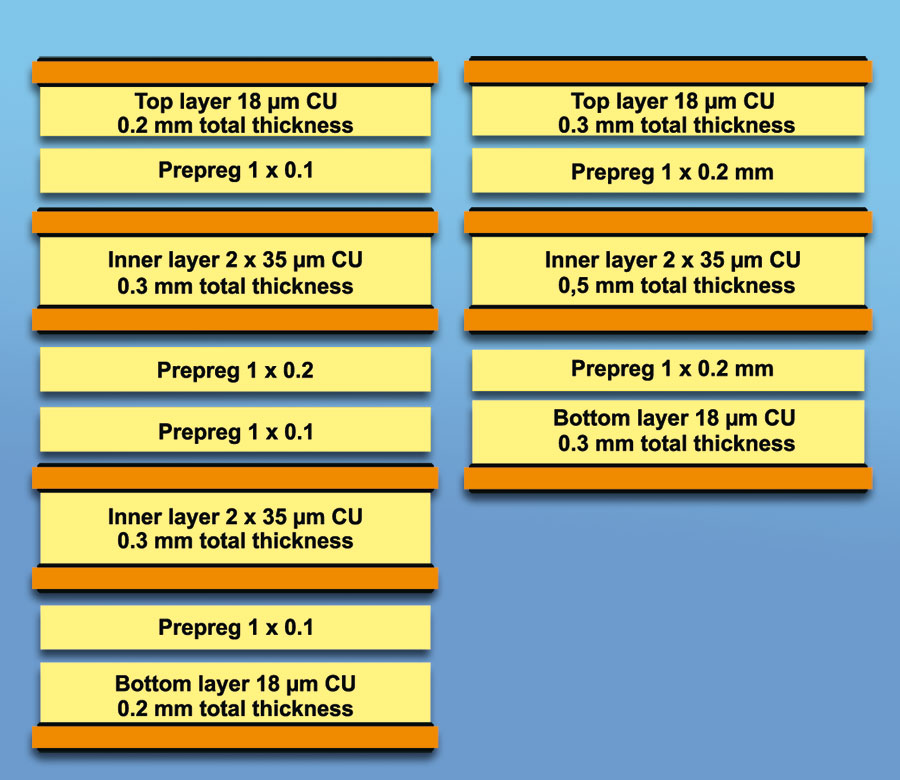

HNumber of layers is only limited by the maximum lift of the press plates (38 mm). Using separating metal sheets one can press a couple of boards over each other at the same time.

A compact and floor standing aluminium rack contains all parts of the unit including pressure supply, press plates and heaters.

The large loading door allows quick and easy access to the press chamber and is of course security switch protected.

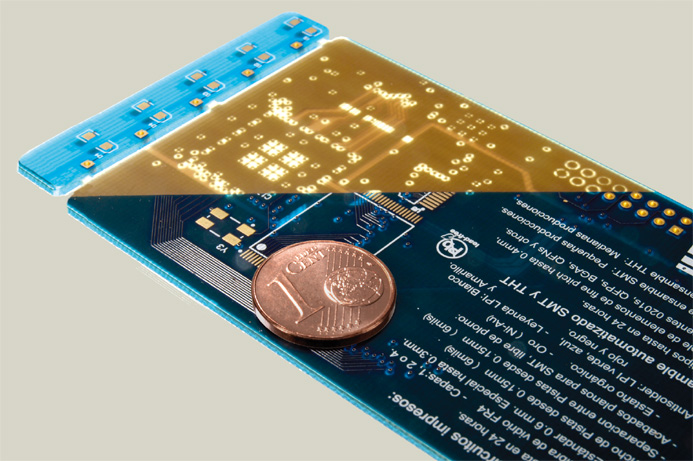

Board size: brutto: 250 x 350 mm

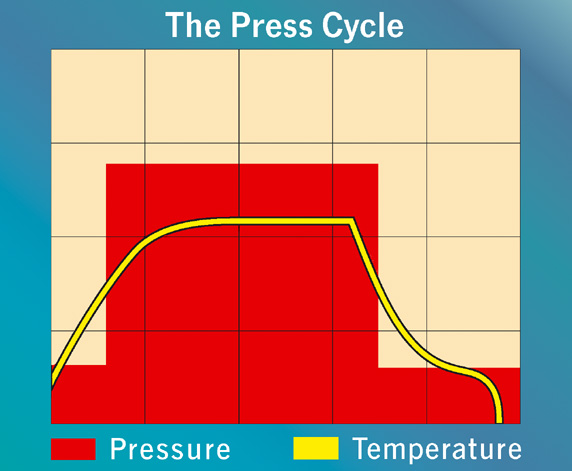

Pressure: > 12 t

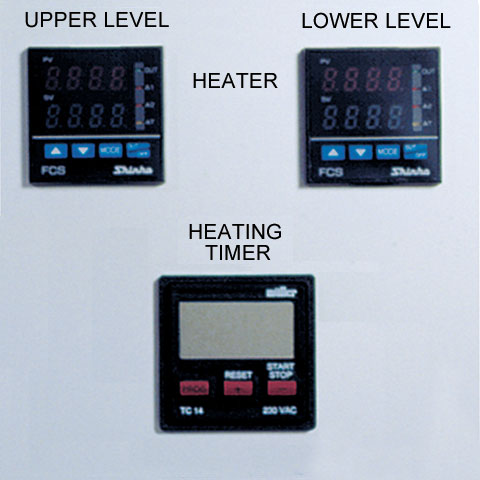

Temperature: max. up to 250°C

Heating up: approx. 30 min.

EN

EN  DE

DE  ES

ES  FR

FR