PCB production with negative resist, galvanic through hole plating (PTH), green solder mask and blue components printing

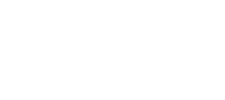

raw material cut to size

(Ne-Cut #1)

CNC-drilling and

contour routing

(BUNGARD CCD/ATC #2)

brushcleaning

(RBM 402 KF #3)

galvanic plating

through hole

(COMPACTA 40 2CU #4)

brushcleaning

(RBM 402 KF #3)

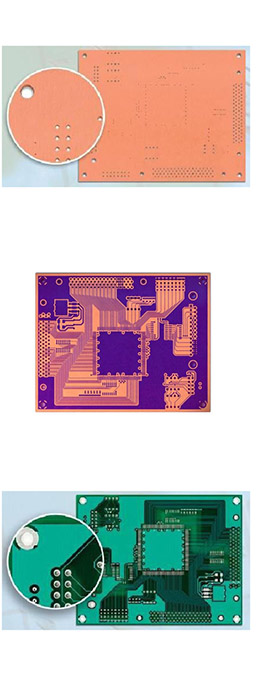

lamination

of tenting resist

(RLM 419p #5)

vacuum exposure

(EXP 3040 LED #6)

spray developing

(DL 500 D #7)

spray etching

(DL 500 #8)

stripping of tenting restist

(DL 500 S #9)

brushcleaning

(RBM 402 KF #3)

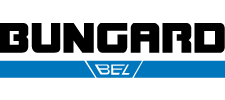

lamination

of solder mask

(RLM 419p #10)

exposure of solder mask

(EXP 3040 #6)

spray developing

(DL 500 D #7)

curing of solder mask

(EXP 3040 #6)

CNC-V-cut or contour routing

(Bungard CCD/ATC #2)

System features:

- Fine-line technology in industrial quality with green solder mask and blue components printing!

- (To make components printing repeat again from laminating but with RLM 419p #1 and blue tenting resist)

- Modular upgradeable to multilayer set, artwork production, waste water treatment or surface finishing at any time !

- Track resolution: better 150µm!

- Film production with laser printer or bubble jet or local film supplier.

- Processing time: approx. 1,5 hours!

- maximales Plattenformat: 300 x 400 mm !

- maximum throughput: 4,5m² / 8h!

- maximum usable size: 300 x 400mm!

EN

EN  DE

DE  ES

ES  FR

FR