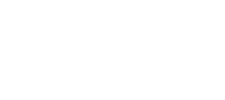

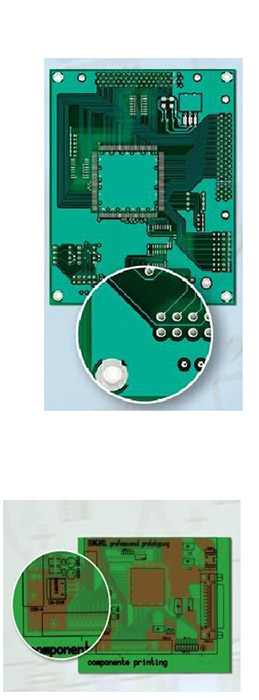

PCBs like in Level 1 - plus green solder mask and blue components printing

additional in Level 2

Original Bungard

positive presensitized boards

CNC-drilling and contour routing

(BUNGARD CCD/2)

vacuum exposure

(HELLAS LED)

dip developing

+ rinsing

+ sprayetching

+ chemical tinning

+ drying

(all in Splash CENTER)

mechanical PTH

(FAVORIT)

lamination

of solder mask

(RLM 419p)

vacuum exposure of solder mask

(HELLAS LED)

spraydeveloping

of solder mask

(SPLASH D)

curing of solder mask

(HELLAS LED or hot air oven)

System features:

Like in Level 1, but in addition:

- Laminator for laminating solder mask and SPLASH D for developing (2 additional machines)

- Components printing: repeat Laminating, exposure and developing with blue tenting resist.

- over all process time: 50 to 120min depending on number of holes

- maximum throughput: 6m² / 8 h

EN

EN  DE

DE  ES

ES  FR

FR